Wheelchair Maintenance: Difference between revisions

No edit summary |

No edit summary |

||

| Line 218: | Line 218: | ||

* Get your suspension professionally inspected if you lose or gain weight significantly. | * Get your suspension professionally inspected if you lose or gain weight significantly. | ||

* Inspect the suspension elements '''monthly.''' | * Inspect the suspension elements '''monthly.''' | ||

'''15- Anti-tippers''' | |||

Anti-tip casters may be used on the front and rear of a wheelchair. When rear anti-tip casters are in use and properly adjusted, if the wheelchair begins to tip over the rear anti-tip casters resist the tipping. Therefore, they can help to prevent some tipping accidents. | |||

Steps: | |||

* Inspect that the pins work, that they can be put on and off, and that the rollers are not broken. | |||

* If problems are identified, contact the wheelchair maintenance expert to have the anti-tip casters replaced. | |||

* If anti-tippers are present, inspect them '''monthly''' | |||

=== Manual Wheelchair Action Maintenance: === | === Manual Wheelchair Action Maintenance: === | ||

| Line 235: | Line 242: | ||

* Always dry the cushion in the shade – not in direct sun. | * Always dry the cushion in the shade – not in direct sun. | ||

* Remove dirt, lint, and hair from the caster axles bearings with scissors, tweezers, toothbrush, or plyers. Dirt, lint, or hair buildup on the axles and casters can eventually cause premature wear. Hair especially can twist around the bearings and cause breakage. | * Remove dirt, lint, and hair from the caster axles bearings with scissors, tweezers, toothbrush, or plyers. Dirt, lint, or hair buildup on the axles and casters can eventually cause premature wear. Hair especially can twist around the bearings and cause breakage. | ||

* This task should be performed '''monthly.''' | |||

{{#ev:youtube|ZMRw-2l9c4A}} | {{#ev:youtube|ZMRw-2l9c4A}} | ||

| Line 247: | Line 255: | ||

* Apply to all moving parts. | * Apply to all moving parts. | ||

* This task should be performed '''four times a year''' | * This task should be performed '''four times a year''' | ||

3-Have wheelchair professional serviced at least '''once a year.''' In places with inclement weather condition, wheelchairs should be professionally serviced '''twice a year.'''{{#ev:youtube|vyuZgxoHhSU}} | |||

* | * | ||

{{#ev:youtube|NmWCtQB_cZc}} | {{#ev:youtube|NmWCtQB_cZc}} | ||

* | * | ||

{{#ev:youtube|-9DGUSz5P5c}} | {{#ev:youtube|-9DGUSz5P5c}} | ||

<div align="justify"> | |||

<div align="justify"> | |||

<div align="justify"> | |||

<div align="justify"> | |||

<div align="justify"> | |||

<div align="justify"><div align="justify"> | |||

<div align="justify"> | |||

=== Power Wheelchair Inspection Maintenance === | |||

'''1- Shrouds''' | |||

Plastic covers or shrouds protect the electronics and battery of the wheelchair. Always keep protective plastic covers (“shrouds”) in place. If the shrouds are damaged, dirt and moisture can impact the proper function of the wheelchair. | |||

Steps: | |||

* Inspect that the shrouds are present and intact. | |||

* Jiggle the shrouds to inspect they are not loose. | |||

* If shrouds become damaged, they should be replaced. | |||

* If you find problems, contact a wheelchair maintenance expert immediately. | |||

* Inspecting the shrouds should be performed '''every day'''. | |||

'''2-Pneumatic tire pressure.''' | |||

For pneumatic (inflatable) tires if the tire lacks sufficient pressure, the wheelchair will be difficult to maneuver and less stable. The tire and wheel will also wear much more quickly. | |||

Steps: | |||

* check the tire pressure by pressing down firmly on the tire with your thumb. | |||

* If the tire is able to be pressed down more than 5mm (roughly the thickness of three pennies stacked together), add air with an air pump. A bicycle pump or pneumatic air pump can be used to inflate wheelchair tires. | |||

* This task should be performed '''weekly.''' | |||

'''3-Nuts and bolts:''' | |||

Nuts and bolts that are too loose will loosen further or not hold the part properly. | |||

Steps: | |||

* Visually identify loose bolts. Move parts and check that they do not rattle. | |||

* Tighten all loose nuts and bolts until snug. | |||

* Depending on the bolt, you can use a screwdriver, wrench or Allen wrench. Tighten to the point where the parts that the nuts and bolts are holding do not move at all. | |||

* Do not over tighten! Some bolts are not to be tightened all the way, such as lock nuts. Over tightening a loose nut or bolt could damage the part and/or bolt. | |||

* Bolts are graded for strength and hardness. The specific grade is selected by the manufacturer for the part where the bolt is to be used. Bolts used on wheelchairs must be replaced with the proper size and type bolt. | |||

* If nuts or bolts are missing, stripped or broken, contact a wheelchair maintenance expert to get the bolts/nuts replaced. | |||

* This task should be performed '''monthly''' | |||

'''4-Frame''' | |||

Steps: | |||

* Inspect the frame and weld points and confirm that they are intact. | |||

* Check the weld points, holes, and bends. | |||

* Look for cracks and fractures as they can result in catastrophic failure of the wheelchair. This could lead to injury and being stranded. | |||

* If you find problems, contact a wheelchair maintenance expert immediately. | |||

* Inspection of the frame should be performed '''monthly.''' | |||

'''5- Tires''' | |||

The wheels have a profound effect on the performance of the wheelchair. Drive tires can be pneumatic tires or solid. | |||

Steps: | |||

* Check for wear on the drive tires. | |||

* When tread depth is low it can easily lead to power chair slippage, making braking distances longer. Wear can also negatively impact the maneuverability and stability of the wheelchair. Therefore replace the tires as early as possible when they are found to have insufficient tread depth. | |||

* Contact a wheelchair maintenance expert to do so. | |||

* This inspection should be performed '''monthly'''. | |||

'''6- Casters''' | |||

The casters have an important effect on the performance of the wheelchair. | |||

Steps: | |||

* Check for wear, cracks, and bulges on the caster wheels. Wear can negatively impact the maneuverability and stability of the wheelchair. | |||

* Caster stem housing should be aligned vertically. | |||

* Check while driving the wheelchair for wobbling of caster wheel and looseness. | |||

* Check for caster flutter. Fluttering is the term used to describe the shimmy or rapid vibration of the caster wheels. Excessive flutter can cause the wheelchair to move in an unwanted direction. This might cause a collision and injure the user. Contact a wheelchair maintenance expert to get repaired. | |||

* Bearings will wear out on a caster wheel during normal use. Problems in the bearings are identified when noises like clicking or grinding are present. They need to be replaced before they fail. | |||

* Caster wheels wear out faster than the drive tires. | |||

* This task should be performed '''monthly'''. | |||

'''7-Anti-tippers''' | |||

Anti-tip wheels may be located in the front or rear of the wheelchair. When they are in use and properly adjusted, if the wheelchair begins to tip over it is caught by the anti-tip casters. Therefore, they can help to prevent some tipping accidents. | |||

Steps: | |||

* Check that the anti-tip wheels are not loose and do not squeak or drag. | |||

* If wheels are loose, tighten any screws until snug using an Allen wrench, open end box end wrench. | |||

* Inspect that there are no cracks or the wheels are not wore out. | |||

* If problems are identified, contact wheelchair maintenance expert to get the anti-tip replaced. | |||

* This task should be performed '''monthly'''. | |||

'''8-Cushion''' | |||

same instructions as manual wheelchair. | |||

'''9-Armrest''' | |||

Same instructions as manual wheelchair. | |||

'''10-Back Support''' | |||

Same instructions as manual wheelchair | |||

'''11-Head support''' | |||

Users may require head and neck supports to provide the necessary stability required to control a power wheelchair and to prevent the head from extending beyond the plane of the back support. This is especially important if the seating system is tilted or reclined. | |||

There are many types of head supports including: flat, flip-down, removable, curved, winged, vertical wedge, U-shaped, lateral, among others. | |||

Head supports are mounted to the seating system using adjustable hardware so that the support can be moved, adjusted, and removed as needed. | |||

Steps: | |||

* Check that the head support is properly tightened and intact. If the head support is designed to move, it should move freely, but not be too loose that it rattles. Loose and/or worn out head supports can be uncomfortable, do not provide appropriate postural support, or can fall out. | |||

* Tighten loose bolts using an Allen wrench, open end box end wrench. | |||

* Lubrication may be necessary in hinges/movable parts if the supports do not adjust easily. | |||

* If problems are identified contact the wheelchair maintenance expert. | |||

* This inspection should be performed '''monthly'''. | |||

'''12-Foot support''' | |||

Foot supports are used to support the feet and legs. There are different foot supports that can flip up or down, swivel, elevate, or can be removed. | |||

Often the foot supports are the first part of the wheelchair to come in contact with an obstacle. They are used to open doors, act as bumpers, and also scraped along the ground when the wheelchair is loaded into a motor vehicle. | |||

Swing-away foot supports are not as durable as rigid foot support. It is common that swing away foot support bend upon impact. | |||

Stesp: | |||

* Inspect the swing away foot supports, look for wear in the pins, bolts and bushings. | |||

* Inspect that the foot supports are intact, are tightened and can be released (if originally designed to do so), put back into place with ease and latch easily. You can use a screwdriver or wrench or Allen wrench to tighten loose bolts. | |||

* Lubrication may be necessary in hinges/movable parts if the supports do not adjust easily. | |||

* If problems are identified, contact the manufacturer. | |||

* This task should be performed '''monthly.''' | |||

'''13-Supporters''' | |||

Proper seating can improve a person’s stamina and provide greater comfort. Supports are used to align and hold a person in a manner that improves seated posture and alignment while maintaining or improving function. These include: abductor pommels, hip adductors, leg abductors, leg adductors, and lateral trunk supports. | |||

Steps: | |||

* If the supports are swing-away or flip-up, inspect that they move freely, but are not too loose to rattle. | |||

* If they are fixed, inspect that they are tightened. | |||

* Loose nuts and bolts can eventually work themselves all the way out, and could cause the support to fall off. However, over tightening a loose nut or bolt could damage the housing and/or break the bolt. | |||

* Tighten loose bolts using an Allen wrench, open end box end wrench. After tightening be aware of red spots on the skin that is in contact with the support. If red spots are found, loosen the support and contact the wheelchair maintenance expert. | |||

* Inspect that the fabric and cushioning of the support are intact. Hard supports may be uncomfortable and increase pressure to the skin that they are in contact with. This can increase the risk of pressure sores. | |||

* If problems are identified, contact the wheelchair maintenance expert. | |||

* This task should be performed '''monthly'''. | |||

'''14-Seat belt''' | |||

Pelvic support and positioning can be achieved using a pelvic belt or lap belt, which can prevent or correct a slouching posture and prevent the person from sliding forward on the seat. | |||

Steps: | |||

* Check that the buckle latches and the hardware that attaches the strap to the frame are undamaged. | |||

* Inspect the strap and velcro (when applicable) for any signs of wear. The strap, buckle, and hardware should all be in good condition. The latch on the belt should not slip or become unlatched inadvertently. | |||

* Contact a wheelchair maintenance expert if problems are identified. | |||

* This task should be performed '''monthly'''. | |||

'''6-Suspension:''' | |||

Dampers or shock absorber springs are used to improve ride comfort, reduce driving fatigue, and accommodate rough terrain. | |||

Steps: | |||

* Inspect springs looking for cracks on the paint. | |||

* Inspect that the dampers are not leaking fluid. | |||

* Be aware that when you are going over obstacles, for example a speed bump, the wheelchair does not make noises and it is safe (at least 3 wheels must be in contact with the ground all the time). | |||

* If problems are identified contact your wheelchair maintenance expert. | |||

* If you have had significant changes in weight this may mean that the suspension is not providing the same damping. Contact a wheelchair maintenance expert if you had significant changes in weight. | |||

* Inspect the suspension '''every 3 months'''. | |||

== '''Common wheelchair and cushion repairs''' == | == '''Common wheelchair and cushion repairs''' == | ||

Revision as of 16:48, 27 May 2018

Original Editor - Mariam Hashem

Top Contributors - Naomi O'Reilly, Mariam Hashem, Kim Jackson, Simisola Ajeyalemi, Shaimaa Eldib, Rucha Gadgil, Amrita Patro, Olajumoke Ogunleye and Robin Tacchetti

Introduction[edit | edit source]

Wheelchair and cushion care is important because it saves costs for repairs, extends their lives and prevents injuries and long-term damage to the user’s body. A wheelchair which is cared for will be more comfortable, energy-efficient and easier to use. A cushion which is cared for will continue to provide pressure relief and support[1].

Between 5 and 18% of wheelchair users experience wheelchair-related injuries each year. Causes of wheelchair-related injuries include tipping over and wheelchair malfunction. In fact, wheelchairs that are poorly maintained increase the risk of their users being injured due to a wheelchair breakdown. Wheelchair users who maintain their wheelchair are 10 times less likely to sustain an injury than those who do not maintain it. repairs and replacement costs account for 30% of the direct wheelchair expenditures annually[2].

Maintenance[edit | edit source]

All wheelchairs require periodic maintenance to operate properly. Some wheelchair parts require periodic repair and replacement[2].

Wheelchair maintenance involve periodic inspection and action. wheelchair service providers must provide training and education for users to detect problems, provide periodic care and should supply them with contact details of repairing professionals.

Periodic maintenance can be classified into inspection and action steps. Inspection means looking for a problem and an action is trying to fix the problem[2].

Manual wheelchair inspection:[edit | edit source]

1- Pneumatic Tires:

properly inflated tires are important for wheelchair propulsion. If the tire lacks sufficient pressure, the wheelchair will be difficult to maneuver, propulsion will take more energy and it will stress the shoulders more. The tire and wheel will also wear much more quickly when the tire is not properly inflated[2].

Steps[2]:

- Check the pressure by pressing down firmly on the tire with your thumb.

- If the tire presses down more than 5mm (roughly the thickness of three pennies stacked together), the tire needs to be inflated.

- Add air to the tire using a bike pump, compressor, or CO2 cartridge. Don't use a gas station air hose. wheelchair tires have very small volume and it is very easy to explode a tire. (4-There are two types of valves used for pneumatic tires on wheelchairs: presta valves and schrader valves. Make sure your air pump has the correct type of valve for your wheelchair)

- Checking the tire pneumatic pressure should be done weekly and more often during winter.

- If you pump your tire and it goes flat right away you may have a hole in the tube. In this case you can either patch it using a patch kit or replace the inner tube for a new one. wheelchair users can be trained on doing this by themselves or contact a maintenance expert.

2-Cushion maintenance

Cushions are a very important component of the wheelchair and do not last as long as the frame. The interaction between the cushion and the body determines the user’s comfort, function, and clinical safety. Deterioration in the cushion can increase the risk of developing a pressure ulcer.

Steps[2]:

- Remove the cover so you can inspect both cushion and cover.

- Look for tears or holes in the cover or zipper malfunction, which might expose the cushion surface or create a wrinkled sitting surface.

- If the cover contains a foam liner, look for tears or flaking in the foam.

- The bottom of most covers has a Velcro or a nonskid surface. Inspect this surface for worn or torn Velcro or breakdown of the nonskid material.

- The cover is designed to protect the cushion, so it should be replaced if damaged.

- After inspecting the cover inspect the cushion for shape and contour.

- This should be done weekly.

There are many types of cushions. Depending on the type there are signs you should look for:

- Keep air cushions properly inflated and inspect that the valve is in good condition and does not leak. If you suspect that there is a leak, remove the cover and submerge the cushion in water and look for bubbles.

- A rubber air cushion (e.g. ROHO) can be patched using a patch kit.

- When you travel by air pay special attention to the cushion because the pressure will change and always travel with a patch kit.

- If you have a gel cushion, knead the gel daily from the outer perimeter to the middle of the cushion. Inspect that the gel is not hard and that there are no leaks.

- If you have a foam cushion, inspect that the foam is intact and not deteriorated and chipping. When you press it, it should bounce back.

- If the cushion has a solid seat insert, check that it is not broken[2].

3-Nuts and bolts:

Most maintenance consists of ensuring that nuts and bolts are properly adjusted. Nuts and bolts that are too loose will loosen further or not hold the part properly.

Steps:

- Visually identify loose bolts.

- Move parts and check that they do not rattle.

- Tighten all loose nuts and bolts until snug.

- Depending on the bolt, you can use a screwdriver, wrench or Allen wrench. Tighten to the point where the parts that the nuts and bolts are holding do not move at all. Do not over tighten!

- Nuts and bolts should be inspected monthly.

4- Tires:

Worn out tires can make the wheelchair harder to propel.

Rear tires can be pneumatic tires or solid. You can determine what type of tire you have by looking at the rim where the air valve sticks out. If there is no valve your tire is solid. If there is a valve you have a pneumatic tire.

Steps:

- Visually inspect the rear tires for wear, cracks, bulges, looseness, damage, and flat spots (In solid tires, it can be hard to see a flat spot on the tire. Usually, you will feel it when rolling on a flat and smooth surface).

- Contact a wheelchair maintenance expert to replace tires when the tread becomes worn, cracked, loose or when the side walls begin to bulge out when pumped with air[2].

5-Wheel bearing:

The wheel bearings allow for free rotation of the wheel around the wheel axis. Therefore, damaged bearings can increase rolling resistance which will make you spend more energy and stress your shoulders more while propelling.

Bearings will wear out on a wheelchair during normal use. Noise is the first thing that will alert you about a wheel bearing that is failing. Most prominently, a knocking noise, and on some occasions, a squeaky squealing moan is what would be the first indicator of such a problem. Initially, the sound would be heard only at certain speeds, but will become fairly regular and prominent as the condition of the bearings worsen.

Steps:

- Inspect that the bearings are working properly.

- Lift one side of the wheelchair off the ground, and spin the wheel, letting it rotate to a stop.

- If the wheel slows and stops quickly when spun, the nut and bolt holding the bearing could be too tight.

- If the wheel slows and rotates backwards slightly when spun, the bearing is not being compressed and it could be too loose.

- Repeat the same procedure with the other wheel.

- If problems are identified, contact a wheelchair maintenance expert to get the bearings replaced.

- This inspection should be performed monthly.

6-spoke.

Through use, spokes can become loosened, damaged, or broken. The spokes should all have equal tension. One loose spoke will cause the others to carry more tension and ultimately the wheel will go out of true (wobble from side to side).

Loose spokes can make the wheelchair harder to propel and/or cause the wheel to collapse. If spoke tension is unequal, you may hear a faint, metallic, snapping sound as you move.

Steps:

- Inspect the spokes monthly by squeezing two together all the way around the wheel. If a spoke “gives” when you squeeze gently, it may be too loose.

- Inspect that the spokes are not bent.

- Inspect that the nipples are tight, not bent or nicked.

- If problems are identified, contact a wheelchair maintenance expert. It is recommended that you do not do this on your own because spokes must be tensioned to a specific torque range and a special stand is used to do this. Otherwise, spokes or their nipples could break and the wheel could go out of true. A bicycle store/shop is useful to get spokes tightened if you have pneumatic tires. If you have solid tires, you need to contact the wheelchair maintenance expert since a new wheel might be the best solution[2].

7-Wheelchair alignment.

Wheel alignment describes the degree to which the rear wheels are parallel to each other and parallel with the center-line of the wheelchair.

Tracking is important as the user pushes on the hand-rims very frequent about once a second. If the wheelchair does not track well, it will drift from its course between pushes and forces the wheelchair user to push more often with one arm than the other to travel straight. This will increase strain on one arm, waste energy, and reduce control over the wheelchair.

Wheelchair users learn how the wheelchair “feels” so they can identify misalignment. The wheelchair should roll straight with no excess drag, pull or side motion. It should not be difficult to push and you should not hear wheel rubbing. When turning, there should be no squeaking, binding, or excessive side motion.

Steps:

- Tracking can be checked by rolling through a puddle of water and allowing the wheelchair to coast.

- The wheelchair should maintain its direction.

- If problems are identified, contact a wheelchair maintenance expert.

- This task should be performed monthly.

8-Wheel locks

Wheel locks act as parking brakes and assist when transferring to other surfaces, or when rider wishes to remain in a particular spot. They allow the rider to be more stable when desired, such as when lifting or pushing things or even simply sitting still.

Steps:

- First inspect that the wheel locks are secured tightly to the frame.

- Apply the lock and check that it holds the tires firmly in place. Note that they are easily activated and that the wheel locks do not interfere with the tire while rolling. Wheel locks that interfere with normal wheel rolling cause wear to the tire and brake.

- This task should be performed monthly.

If you find any problem while inspecting the wheel locks:

- Adjust wheel locks if they are loose or not working properly.

- Use an open-box wrench and/or Allen wrench to adjust as necessary.

- If the locks still do not work properly, contact the wheelchair maintenance expert.

9-hand-rim

Hand-rims are metal or plastic rings that are attached to the rear wheels and used to propel a manual wheelchair.

Steps:

- Inspect the hand-rims for wear, dents, or bends. Cracks can cut or harm the user, if found, contact a wheelchair maintenance expert to have the hand-rim replaced.

- Inspect if they are loose. You can feel that they are loose while you propel. A loose hand-rim can make it more difficult to grasp and may fall off.

- You can tighten the hand-rim using an open-end wrench or a screwdriver. If unable to do so contact the wheelchair maintenance expert.

- This inspection should be performed monthly

10-Wheelchair caster

The caster wheels have an important effect on the performance of the wheelchair. Worn out caster wheels can make the wheelchair harder to propel.

Steps:

- Inspect casters wheels for wear, cracks, looseness, bulges, and tears.

- Inspect that the casters wheels are evenly touching the floor when on a flat surface.

- When one of the casters wheels does not touch the floor while on level ground, the wheelchair has caster float. This decreases the stability and performance of the wheelchair.

- Inspect that the caster stem housing is aligned vertically.

- If you find problems contact the wheelchair maintenance expert.

- Inspect the front caster caps; these caps protect the caster assembly from moisture and water. If they come off, contact the wheelchair maintenance expert.

- This task should be performed monthly.

11- Foot support

Often the foot supports are the first part of the wheelchair to come in contact with an obstacle. They are used to open doors, act as bumpers, and are often scraped along the ground when the wheelchair is loaded into a motor vehicle or during mobility techniques such as wheelies, curb cuts, and sharp inclination changes such as the end of ramps.

Cross-brace-frame wheelchairs typically have foot supports that can flip up or down, swivel, are angle-adjustable, or can be removed, whereas rigid-frame wheelchairs have the foot support built into the frame.

Rigid foot supports are normally are not removable, but the height often can be slightly adjusted to accommodate various leg lengths. Swing-away foot support are not as durable as rigid foot support.

Steps:

- Inspect that the foot supports are intact, tightened and can be released (if originally designed to do so), put back into place with ease and that they latch properly.

- Inspect the swing away foot support, look for wear in the pin, bolt and bushing in this mechanism.

- You can use a screwdriver, wrench or Allen wrench to tighten loose bolts.

- If problems are identified, contact the wheelchair maintenance expert.

- This task should be performed monthly.

12- Armrest

The primary purpose of the arm support is to provide good resting posture for the arms. In addition, arm supports provide a form of support and are convenient handles when the rider leans to one side or the other. They are also helpful when attempting to reach higher places, and they also assist some people with transfers.

Arm supports can be fixed or adjustable. Most can be removed or flipped out of the way in order to provide clearance for transferring in and out of the wheelchair.

Removable arm supports usually fit into one or two sockets. Commonly, if there are two attachment points, the front socket contains a latch to lock the armrest in place.

Flip back arm supports are hinged at the back near the intersection of the seat and backrest. Some flip back supports use the latch in the front to help secure them in place.

Steps:

- Inspect that the arm supports are intact, tightened and can be released (if originally designed to do so), put back into place with ease, and latch easily.

- Inspect for sharp edges that could cause harm.

- Loose arm supports can make the user fall when using them for support during transfers.

- Tighten as necessary.

- If a problem is identified, contact the wheelchair maintenance expert.

- This inspection should be performed monthly

13-Back support

Back supports provide comfort and postural support while sitting. Back supports can be sling upholstery or rigid.

For upholstery back supports:

- Inspect it for wear, tears, stretched upholstery, or metal parts that may be sticking out.

- Inspect all upholstery rivets or screws and check that the upholstery is not tearing in those spots.

- Loose upholstery may provide less postural support and can lead to skeletal deformities.

- Contact a wheelchair maintenance expert to replace the upholstery when these problems are identified.

- When the upholstery is replaced, it is best to replace the bolts or screws that hold it in place. This will ensure that they are properly maintained as well.

For rigid back supports;

- Inspect the surface is intact.

- Inspect that the back support hardware is properly attached to the back support posts and does not rattle.

- Tighten loose bolts with a screw driver, Allen wrench, or wrench.

- If the fabric is worn out and/or the foam is rigid, contact the wheelchair maintenance expert to get a replacement.

- The back support should be inspected monthly.

Most rigid-frame wheelchairs have a foldable back support for transport and storage. If you have a folding back support, check that the mechanism lock is in place. Loose back supports can be dangerous during transfers because they could move or come out. Always make sure that the back support is locked before using it after unfolding the back. If problems are identified contact your wheelchair maintenance expert to get it fixed or replaced.

14-Folding frame

Cross-brace frames allow for the wheelchair to collapse towards the middle for storage.

Steps:

- Inspect that the cross brace mechanism is working properly every time you use it. It should open and fold easily, If it is difficult to close or if the wheelchair is unsteady during transfers.

- Problems with the cross-brace mechanism may cause the wheelchair to collapse and injury to the user.

- If problems are identified, contact a wheelchair maintenance expert.

- If you do not fold the wheelchair frequently, this task should be performed monthly

- Some frames have built in or “add-on” suspension elements to decrease shock and vibration and make for a smoother ride.

- Inspect that the paint in the spring is intact and it has no cracks.

- Inspect that the damper is not leaking lubricant.

- Contact the wheelchair maintenance expert if you find any problems.

- Get your suspension professionally inspected if you lose or gain weight significantly.

- Inspect the suspension elements monthly.

15- Anti-tippers

Anti-tip casters may be used on the front and rear of a wheelchair. When rear anti-tip casters are in use and properly adjusted, if the wheelchair begins to tip over the rear anti-tip casters resist the tipping. Therefore, they can help to prevent some tipping accidents.

Steps:

- Inspect that the pins work, that they can be put on and off, and that the rollers are not broken.

- If problems are identified, contact the wheelchair maintenance expert to have the anti-tip casters replaced.

- If anti-tippers are present, inspect them monthly

Manual Wheelchair Action Maintenance:[edit | edit source]

1. Clean the wheelchair and cushion: to protect metal and wooden parts from rusting and rotting and stop damage caused by dirt scraping against moving parts.

STEPS:

- Use warm water with a little soap.

- Rinse and dry.

- Pay attention to moving parts, and where upholstery joins the frame.

- Remove cushion from cover and wash separately.

- Always dry the cushion in the shade – not in direct sun.

- Remove dirt, lint, and hair from the caster axles bearings with scissors, tweezers, toothbrush, or plyers. Dirt, lint, or hair buildup on the axles and casters can eventually cause premature wear. Hair especially can twist around the bearings and cause breakage.

- This task should be performed monthly.

2. Lubricate moving parts: to stop rust and keep parts moving smoothly. Increased friction between moving parts can accelerate wear of the moving parts.

STEPS:

- Clean, dry, and apply lubricating oil or Teflon-based spray to all moving parts, including the folding mechanism, where the front casters turn, and exposed hinges.

- Use a lubricating oil, for example bearing oil.

- DO NOT lubricate sealed bearings!

- DO NOT use penetrating oil!

- Use a rag to remove excess lubricant.

- Apply to all moving parts.

- This task should be performed four times a year

Power Wheelchair Inspection Maintenance[edit | edit source]

1- Shrouds

Plastic covers or shrouds protect the electronics and battery of the wheelchair. Always keep protective plastic covers (“shrouds”) in place. If the shrouds are damaged, dirt and moisture can impact the proper function of the wheelchair.

Steps:

- Inspect that the shrouds are present and intact.

- Jiggle the shrouds to inspect they are not loose.

- If shrouds become damaged, they should be replaced.

- If you find problems, contact a wheelchair maintenance expert immediately.

- Inspecting the shrouds should be performed every day.

2-Pneumatic tire pressure.

For pneumatic (inflatable) tires if the tire lacks sufficient pressure, the wheelchair will be difficult to maneuver and less stable. The tire and wheel will also wear much more quickly.

Steps:

- check the tire pressure by pressing down firmly on the tire with your thumb.

- If the tire is able to be pressed down more than 5mm (roughly the thickness of three pennies stacked together), add air with an air pump. A bicycle pump or pneumatic air pump can be used to inflate wheelchair tires.

- This task should be performed weekly.

3-Nuts and bolts:

Nuts and bolts that are too loose will loosen further or not hold the part properly.

Steps:

- Visually identify loose bolts. Move parts and check that they do not rattle.

- Tighten all loose nuts and bolts until snug.

- Depending on the bolt, you can use a screwdriver, wrench or Allen wrench. Tighten to the point where the parts that the nuts and bolts are holding do not move at all.

- Do not over tighten! Some bolts are not to be tightened all the way, such as lock nuts. Over tightening a loose nut or bolt could damage the part and/or bolt.

- Bolts are graded for strength and hardness. The specific grade is selected by the manufacturer for the part where the bolt is to be used. Bolts used on wheelchairs must be replaced with the proper size and type bolt.

- If nuts or bolts are missing, stripped or broken, contact a wheelchair maintenance expert to get the bolts/nuts replaced.

- This task should be performed monthly

4-Frame

Steps:

- Inspect the frame and weld points and confirm that they are intact.

- Check the weld points, holes, and bends.

- Look for cracks and fractures as they can result in catastrophic failure of the wheelchair. This could lead to injury and being stranded.

- If you find problems, contact a wheelchair maintenance expert immediately.

- Inspection of the frame should be performed monthly.

5- Tires

The wheels have a profound effect on the performance of the wheelchair. Drive tires can be pneumatic tires or solid.

Steps:

- Check for wear on the drive tires.

- When tread depth is low it can easily lead to power chair slippage, making braking distances longer. Wear can also negatively impact the maneuverability and stability of the wheelchair. Therefore replace the tires as early as possible when they are found to have insufficient tread depth.

- Contact a wheelchair maintenance expert to do so.

- This inspection should be performed monthly.

6- Casters

The casters have an important effect on the performance of the wheelchair.

Steps:

- Check for wear, cracks, and bulges on the caster wheels. Wear can negatively impact the maneuverability and stability of the wheelchair.

- Caster stem housing should be aligned vertically.

- Check while driving the wheelchair for wobbling of caster wheel and looseness.

- Check for caster flutter. Fluttering is the term used to describe the shimmy or rapid vibration of the caster wheels. Excessive flutter can cause the wheelchair to move in an unwanted direction. This might cause a collision and injure the user. Contact a wheelchair maintenance expert to get repaired.

- Bearings will wear out on a caster wheel during normal use. Problems in the bearings are identified when noises like clicking or grinding are present. They need to be replaced before they fail.

- Caster wheels wear out faster than the drive tires.

- This task should be performed monthly.

7-Anti-tippers

Anti-tip wheels may be located in the front or rear of the wheelchair. When they are in use and properly adjusted, if the wheelchair begins to tip over it is caught by the anti-tip casters. Therefore, they can help to prevent some tipping accidents.

Steps:

- Check that the anti-tip wheels are not loose and do not squeak or drag.

- If wheels are loose, tighten any screws until snug using an Allen wrench, open end box end wrench.

- Inspect that there are no cracks or the wheels are not wore out.

- If problems are identified, contact wheelchair maintenance expert to get the anti-tip replaced.

- This task should be performed monthly.

8-Cushion

same instructions as manual wheelchair.

9-Armrest

Same instructions as manual wheelchair.

10-Back Support

Same instructions as manual wheelchair

11-Head support

Users may require head and neck supports to provide the necessary stability required to control a power wheelchair and to prevent the head from extending beyond the plane of the back support. This is especially important if the seating system is tilted or reclined.

There are many types of head supports including: flat, flip-down, removable, curved, winged, vertical wedge, U-shaped, lateral, among others.

Head supports are mounted to the seating system using adjustable hardware so that the support can be moved, adjusted, and removed as needed.

Steps:

- Check that the head support is properly tightened and intact. If the head support is designed to move, it should move freely, but not be too loose that it rattles. Loose and/or worn out head supports can be uncomfortable, do not provide appropriate postural support, or can fall out.

- Tighten loose bolts using an Allen wrench, open end box end wrench.

- Lubrication may be necessary in hinges/movable parts if the supports do not adjust easily.

- If problems are identified contact the wheelchair maintenance expert.

- This inspection should be performed monthly.

12-Foot support

Foot supports are used to support the feet and legs. There are different foot supports that can flip up or down, swivel, elevate, or can be removed.

Often the foot supports are the first part of the wheelchair to come in contact with an obstacle. They are used to open doors, act as bumpers, and also scraped along the ground when the wheelchair is loaded into a motor vehicle.

Swing-away foot supports are not as durable as rigid foot support. It is common that swing away foot support bend upon impact.

Stesp:

- Inspect the swing away foot supports, look for wear in the pins, bolts and bushings.

- Inspect that the foot supports are intact, are tightened and can be released (if originally designed to do so), put back into place with ease and latch easily. You can use a screwdriver or wrench or Allen wrench to tighten loose bolts.

- Lubrication may be necessary in hinges/movable parts if the supports do not adjust easily.

- If problems are identified, contact the manufacturer.

- This task should be performed monthly.

13-Supporters

Proper seating can improve a person’s stamina and provide greater comfort. Supports are used to align and hold a person in a manner that improves seated posture and alignment while maintaining or improving function. These include: abductor pommels, hip adductors, leg abductors, leg adductors, and lateral trunk supports.

Steps:

- If the supports are swing-away or flip-up, inspect that they move freely, but are not too loose to rattle.

- If they are fixed, inspect that they are tightened.

- Loose nuts and bolts can eventually work themselves all the way out, and could cause the support to fall off. However, over tightening a loose nut or bolt could damage the housing and/or break the bolt.

- Tighten loose bolts using an Allen wrench, open end box end wrench. After tightening be aware of red spots on the skin that is in contact with the support. If red spots are found, loosen the support and contact the wheelchair maintenance expert.

- Inspect that the fabric and cushioning of the support are intact. Hard supports may be uncomfortable and increase pressure to the skin that they are in contact with. This can increase the risk of pressure sores.

- If problems are identified, contact the wheelchair maintenance expert.

- This task should be performed monthly.

14-Seat belt

Pelvic support and positioning can be achieved using a pelvic belt or lap belt, which can prevent or correct a slouching posture and prevent the person from sliding forward on the seat.

Steps:

- Check that the buckle latches and the hardware that attaches the strap to the frame are undamaged.

- Inspect the strap and velcro (when applicable) for any signs of wear. The strap, buckle, and hardware should all be in good condition. The latch on the belt should not slip or become unlatched inadvertently.

- Contact a wheelchair maintenance expert if problems are identified.

- This task should be performed monthly.

6-Suspension:

Dampers or shock absorber springs are used to improve ride comfort, reduce driving fatigue, and accommodate rough terrain.

Steps:

- Inspect springs looking for cracks on the paint.

- Inspect that the dampers are not leaking fluid.

- Be aware that when you are going over obstacles, for example a speed bump, the wheelchair does not make noises and it is safe (at least 3 wheels must be in contact with the ground all the time).

- If problems are identified contact your wheelchair maintenance expert.

- If you have had significant changes in weight this may mean that the suspension is not providing the same damping. Contact a wheelchair maintenance expert if you had significant changes in weight.

- Inspect the suspension every 3 months.

Common wheelchair and cushion repairs[edit | edit source]

Wheelchairs and cushions will sometimes need to be repaired. Wheelchair service personnel need to be able to either carry out a repair, or advise wheelchair users where they can get help. Provide patients with available local places where they can repair wheelchairs.Possible places or people are:

• Bicycle repairer;

• Motorcycle or car mechanic;

• Workshops – welder, plumber (metal parts), carpenter, furniture maker

(wooden parts);

• Wheelchair user, wheelchair user’s family member, relative or neighbor;

• Tailor for repairing upholstery;

• Wheelchair service facilities.

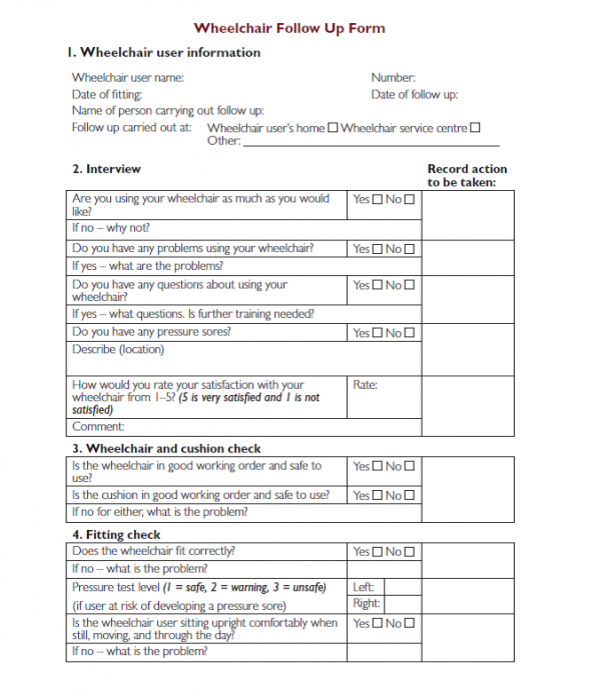

Wheelchair Follow up[edit | edit source]

Follow up happens after the wheelchair user has received their wheelchair and has been using it for a while. Follow up appointments are an opportunity to gather information from the wheelchair user, check that the wheelchair is in good working order and check the fitting of the wheelchair.

Research has shown that approximately 60% of wheelchair users have reported a needing a wheelchair repair in the previous 6 months.**

All users will benefit from a follow up visit, particularly children, users at risk of developing a pressure sore, users who have a progressive condition and those who have had difficulty with any of the training or instruction given to them.

Most intermediate level wheelchair users need additional postural support, and therefore follow up is particularly important.

There is no rule about when follow up should happen though one follow up session within six weeks of the date of delivery is often found to be useful. It will depend on the needs of the user. However, for children, it is ideal if follow up occurs every six months. This is because the needs of children change quickly as they grow.

Follow up can be carried out either at a home visit, at a center or at any other location that suits the user and the wheelchair personnel.

At the follow up the wheelchair service personnel should check that the wheelchair is in good order, provide more tips or training. If needed the service provider may re-adjust the wheelchair, carry out minor repairs or home maintenance, organize major repairs or assist the wheelchair user to arrange for repairs[1].

Ways to manage follow up appointments

- Give wheelchair users a follow up appointment when they receive their wheelchair[3].

- Visit wheelchair users at home for follow up, where possible.

- Make follow up visits part of routine visits to communities by community-based rehabilitation (CBR) personnel who have been trained to carry out follow up.

- Arrange a follow up phone call if transport is difficult and the wheelchair user has access to a phone

References[edit | edit source]

- ↑ 1.0 1.1 WHO Library Cataloguing-in-Publication Data. Wheelchair service training package: basic level / edited by Chapal Khasnabis and Kylie Mines

- ↑ 2.0 2.1 2.2 2.3 2.4 2.5 2.6 2.7 2.8 May, R. M. (2017). Wheelchair Maintenance Training program ( WMTP ) Clinician ’ s Reference Manual.

- ↑ WHO Library Cataloguing-in-Publication Data. Wheelchair service training package: intermediate level / edited by Chapal Khasnabis and Kylie Mines.